- Laminated Busbar

- Film Capacitor

- Film Capacitor for HEV / EV Motor Control Unit

- DC-Link Capacitor ( Dry-Type, Plastic Case, Maximum Temperature 85℃)

- DC-Link Capacitor ( Dry-Type, Plastic Case, Maximum Temperature 105℃)

- MKP DC-Link Film Capacitor

- Water Cooled Heat Sink

- Flat Heat Pipe

- Reactor

- Water Cooling Reactor

- Input AC Reactor

- Output AC Reactor

- DC Reactor

- Reactor for Explosion-Proof Inverter

- Sine Wave Filter

- Detuned Reactor

- DV/DT Filters

- Three-Phase Input Filter

- Resistor

- Wirewound Resistor

- Aluminum Enclosure Resistor

- Aluminum Housed Resistor

- Die-Casting Aluminum Resistor

- Aluminium Resistor (Multiple Unit)

- Thick Film Resistor

- Braking Resistor Box

- Wirewound Tubular Fixed Resistor

- Power Resistor Unit

- Crowbar Resistor

- Braking Unit

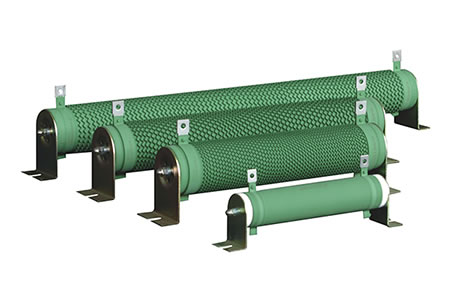

Wirewound Resistor

Product Profile

The wirewound resistor is made by fixing two leading-out terminals on the cylindrical ceramic tube which is coiled by bandlet and wave shape alloy resistance wire. The surface of the ceramic tube is coated by a layer of coating which is resistant to flaming and high temperature. As the framework of the resistance wire, the ceramic tube can also work as the radiator. This product can be made to order. It is suitable for simulated load test, the discharging of equipment, automatic control and the dynamic braking of the transducer.

Features

1. Rated power range: 50W-2500W

2. Operating voltage range: <1.2kV

3. Rated resistance range: 1R-10KR

4. Electric strength: AC3KV 50Hz/5s

5. IP Grade: IP00

6. Element Material: 0Cr25AL5

7. Advantage: It can be used in high voltage class

8. Disadvantage: Relatively poor vibration resistance

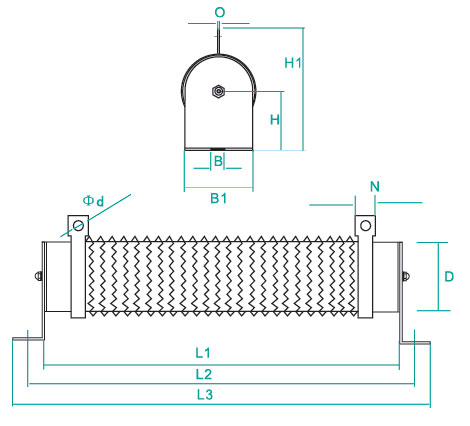

Product Size

Product Size

Applicable Standard

GB/T5729-1994 Fixed resistor used in electronic equipment

| (W)Rated Power(A) | Dimension (mm) | Weight (kg) | Resistance Range(Ω) |

||||||||||

| L1(±2) | L2(±5) | L3(±3) | D(±2) | B | B1 | H | H1(±3) | N | Φ d | O | |||

| 50 | 102 | 124 | 146 | 28 | 6.5 | 28 | 28 | 62 | 9.5 | 4.5 | 1.2 | 0.15 | 1Ω-10KΩ |

| 60 | 102 | 124 | 146 | 28 | 6.5 | 28 | 28 | 62 | 9.5 | 4.5 | 1.2 | 0.2 | 1Ω-10KΩ |

| 80 | 152 | 174 | 196 | 28 | 6.5 | 28 | 28 | 62 | 9.5 | 4.5 | 1.2 | 0.24 | 1Ω-10KΩ |

| 100 | 182 | 204 | 226 | 28 | 6.5 | 28 | 28 | 62 | 9.5 | 4.5 | 1.2 | 0.24 | 1Ω-10KΩ |

| 120 | 182 | 204 | 226 | 28 | 6.5 | 28 | 28 | 62 | 9.5 | 4.5 | 1.2 | 0.24 | 1Ω-10KΩ |

| 150 | 197 | 219 | 241 | 28 | 8 | 40 | 41 | 86 | 12 | 5.5 | 2 | 0.43 | 1Ω-10KΩ |

| 200 | 197 | 219 | 241 | 40 | 8 | 40 | 41 | 86 | 12 | 5.5 | 2 | 0.43 | 1Ω-10KΩ |

| 300 | 284 | 306 | 328 | 40 | 8 | 40 | 41 | 86 | 12 | 5.5 | 2 | 0.62 | 1Ω-10KΩ |

| 400 | 284 | 306 | 328 | 40 | 8 | 40 | 41 | 86 | 12 | 5.5 | 2 | 0.62 | 1Ω-10KΩ |

| 500 | 318 | 340 | 362 | 40 | 8 | 50 | 45 | 99 | 16 | 6..5 | 2 | 0.7 | 1Ω-10KΩ |

| 600 | 347 | 369 | 391 | 50 | 8 | 40 | 41 | 86 | 12 | 5.5 | 2 | 0.96 | 1Ω-10KΩ |

| 750 | 318 | 340 | 362 | 40 | 8 | 50 | 45 | 99 | 16 | 6.5 | 2 | 0.96 | 1Ω-10KΩ |

| 1000 | 302 | 327 | 352 | 60 | 8.5 | 60 | 60 | 119 | 16 | 6.5 | 2 | 1.4 | 5Ω-10KΩ |

| 1200 | 417 | 442 | 467 | 60 | 8.5 | 60 | 60 | 119 | 16 | 6.5 | 2 | 1.4 | 5Ω-10KΩ |

| 1500 | 417 | 442 | 467 | 60 | 8.5 | 60 | 60 | 119 | 16 | 6.5 | 2 | 1.72 | 5Ω-10KΩ |

| 2000 | 512 | 537 | 562 | 60 | 8.5 | 60 | 60 | 119 | 16 | 6.5 | 2 | 2.02 | 5Ω-10KΩ |

| 2500 | 602 | 627 | 652 | 60 | 8.5 | 60 | 60 | 119 | 16 | 6.5 | 2 | 2.45 | 5Ω-10KΩ |

Products in ROHS dimension should be described in the order. For any demand of other technical parameters please contact us.

Identification Code of the Finish Product| RXHG | 2K00 | 0032 | 9999M | K |

| Product Type | Rated Power 50W-2500W 0020-20W 2K00-2KW |

Resistance Value(ohm) (Ω)indicates resistance value in units of ohms 0R08-0.08Ω/ 0032-32Ω/8K00-8KΩ |

Connection M= Terminal | Resistance Tolerance H=±3% K=±10% J=±5% |

RXHG.2K00.0032.9999M (9999M stands for standard product 2KW/32R corrugation electrical resistor)

RXHG.2K00.0032.6218A (6218A stands for 6218 non-standard product 2KW/32R corrugation electrical resistor)

| Property | Inspection method | Performance requirements | Test method |

| Constant humidity-heat | Temperature 40 °C , RH90% 96h | R≤±(5%±0.05Ω) | GB5729.2.24 |

| Temperature change | -55 ° C to +55 °C , 3 Cycles | R≤±(2%±0.05Ω) | GB5729.4.19 |

| Transient overload | (10 Times that of Pr 5s) | No visible destruction R≤±(1%±0.05Ω) | GB5729.4.13 |

| Insulation resistance | DC 1000V | R≥100MΩ | GB5729.4.6 |

| Voltage resistibility | AC2000V 50Hz 5s | Free of breakage or flying arc | GB5729.4.7 |

| Life | 25 ° C Ur 1000h | R≤20% | |

| Terminal strength | 45N 30S | R≤±(1%R+0.05Ω) Free of visible destruction | GB5729.4.16 |

| Resistor strength | 200N 30S | Free of visible destruction | GB5729.4.15 |

| Vibration resistibility | f:5-200HZ a=3g X.Y.Z every 2h | R≤±(1%R+0.05Ω) Free of visible destruction | IEC-6072/-3-32002 |