- Laminated Busbar

- Film Capacitor

- Film Capacitor for HEV / EV Motor Control Unit

- DC-Link Capacitor ( Dry-Type, Plastic Case, Maximum Temperature 85℃)

- DC-Link Capacitor ( Dry-Type, Plastic Case, Maximum Temperature 105℃)

- MKP DC-Link Film Capacitor

- Water Cooled Heat Sink

- Flat Heat Pipe

- Reactor

- Water Cooling Reactor

- Input AC Reactor

- Output AC Reactor

- DC Reactor

- Reactor for Explosion-Proof Inverter

- Sine Wave Filter

- Detuned Reactor

- DV/DT Filters

- Three-Phase Input Filter

- Resistor

- Wirewound Resistor

- Aluminum Enclosure Resistor

- Aluminum Housed Resistor

- Die-Casting Aluminum Resistor

- Aluminium Resistor (Multiple Unit)

- Thick Film Resistor

- Braking Resistor Box

- Wirewound Tubular Fixed Resistor

- Power Resistor Unit

- Crowbar Resistor

- Braking Unit

Die-Casting Aluminum Resistor

Product Profile

REHT series aluminum die-casting resistors are applicable in harsh environments, which are superior to traditional aluminum enclosure resistors in resistance to vibration, protection grade, impact resistance, small heat resistance, applicable to the buffer of the electric heating module, conversion braking, servo system, etc.

Features

1. Rated power range: 60W-2000W

2. Operating voltage range: ≤690V

3. Range of rated resistance value: 2Ω-500Ω

4. Electric Strength: AC2000V 50Hz/5S

5. IP Grade: IP00/IP54

6. Advantages: high protection level, good vibration resistance, low heat resistance and excellent impact resistance.

7. Disadvantages: low voltage grade

Technical Parameters

Technical Parameters| Type | Rated Power (W) |

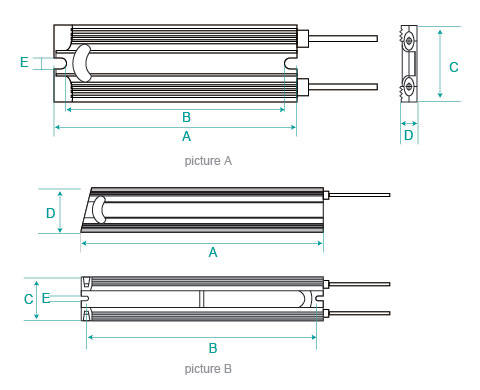

Product Picture |

Dimension (mm) | Connecting Wire (mm) |

Lead length (mm) |

Terminal | Weight (Kg) | Resistance Value (Ω) |

||||

| A | B | C | D | E | ||||||||

| REHT | 60 | Picture A | 115 | 98 | 38 | 14 | 5.5 | 2.5 | 500 | 2-5S | 0.25 | 2Ω-100Ω |

| REHT | 80 | 115 | 98 | 38 | 14 | 5.5 | 2.5 | 500 | 2-5S | 0.25 | 2Ω-100Ω | |

| REHT | 100 | 165 | 148 | 38 | 14 | 5.5 | 2.5 | 500 | 2-5S | 0.25 | 2Ω-100Ω | |

| REHT | 120 | 165 | 148 | 38 | 14 | 5.5 | 2.5 | 500 | 2-5S | 0.27 | 2Ω-100Ω | |

| REHT | 150 | 215 | 198 | 38 | 14 | 5.5 | 2.5 | 500 | 2-5S | 0.31 | 2Ω-100Ω | |

| REHT | 200 | 165 | 147 | 60 | 23 | 5.5 | 2.5 | 500 | 2-5S | 0.46 | 2Ω-200Ω | |

| REHT | 300 | 215 | 198 | 60 | 23 | 5.5 | 2.5 | 500 | 2-5S | 0.58 | 2Ω-200Ω | |

| REHT | 400 | 265 | 247 | 60 | 23 | 5.5 | 2.5 | 500 | 2-5S | 0.74 | 2Ω-200Ω | |

| REHT | 500 | 335 | 317 | 60 | 23 | 5.5 | 2.5 | 500 | 2-5S | 0.94 | 2Ω-200Ω | |

| REHT | 800 | 400 | 384 | 50 | 50 | 5.5 | 4 | 500 | 3.5-6S | 1.37 | 2Ω-500Ω | |

| REHT | 1000 | Picture B | 400 | 384 | 50 | 50 | 5.5 | 4 | 500 | 3.5-6S | 1.37 | 2Ω-500Ω |

| REHT | 1200 | 485 | 384 | 50 | 50 | 5.5 | 4 | 500 | 3.5-6S | 1.37 | 2Ω-500Ω | |

| REHT | 1500 | 485 | 469 | 50 | 50 | 5.5 | 4 | 500 | 3.5-6S | 1.59 | 2Ω-500Ω | |

| REHT | 2000 | 550 | 534 | 50 | 50 | 5.5 | 4 | 500 | 3.5-6S | 1.77 | 2Ω-500Ω | |

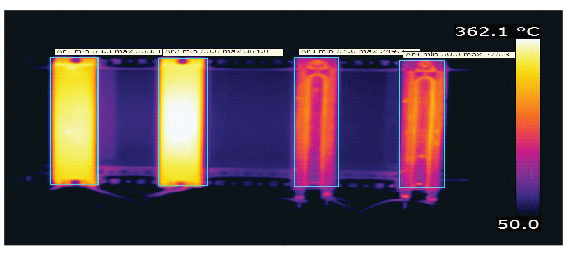

Infrared test images: even temperature distribution and lower temperature rise compared with traditional ones

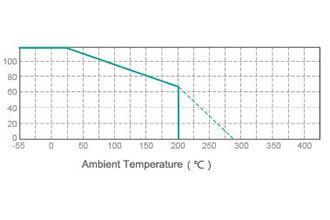

Derating Curve

Derating Curve

Rated Ratio of Power Loss (%) Surface Temperature Rise

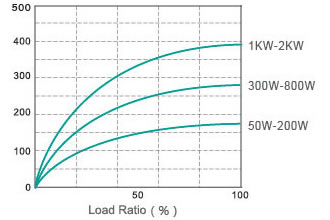

Surface Temperature Rise

Temperature Rise

| Property | Inspection method | Performance Requirement | Test method |

| Constant damp-heat | 40℃ Relative Humidity 90% 96h | R≤±(5%±0.05Ω) | GB5729.2.24 |

| Quick change of temperature | -55℃+55℃ 3 circulations | R≤±(2%±0.05Ω) | GB5729.4.19 |

| Transient overload | 10 times Pr 5S | No visible damage R≤±(1%±0.05Ω) | GB5729.4.13 |

| Insulated resistance | DC 1000V | R≥100MΩ | GB5729.4.6 |

| Electric strength | AC2000V 50Hz 5s | Free of puncture or electrical flashover | GB5729.4.7 |

| Life | 25℃ Ur 1000h | R≤20% | |

| Terminal strength | 45N 30S | R≤±(1%R+0.05Ω) Free of visible destruction | GB5729.4.16 |

| Resistor strength | 200N 30S | Free of visible damage | GB5729.4.15 |

| Vibration resistance | f:5-200HZ a=3g (2h testing for X.Y.Z respectively) | R≤±(1%R+0.05Ω) Free of visible damage | IEC-6072/-3-32002 |

| REHT | 2000W | 20R | K | M |

| Product Type | Rated Power 50W-2000W 0020-20W 2K00-2KW |

Resistance Value(ohm) (Ω)stands for resistance value in the unit of ohm(s) 0R08-0.08Ω/0032-32Ω/8K00-8KΩ |

Resistance Tolerance H=±3% K=±10% J=±5% |

Connection H= Lead |