- Laminated Busbar

- Film Capacitor

- Film Capacitor for HEV / EV Motor Control Unit

- DC-Link Capacitor ( Dry-Type, Plastic Case, Maximum Temperature 85℃)

- DC-Link Capacitor ( Dry-Type, Plastic Case, Maximum Temperature 105℃)

- MKP DC-Link Film Capacitor

- Water Cooled Heat Sink

- Flat Heat Pipe

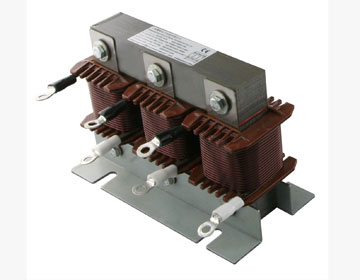

- Reactor

- Water Cooling Reactor

- Input AC Reactor

- Output AC Reactor

- DC Reactor

- Reactor for Explosion-Proof Inverter

- Sine Wave Filter

- Detuned Reactor

- DV/DT Filters

- Three-Phase Input Filter

- Resistor

- Wirewound Resistor

- Aluminum Enclosure Resistor

- Aluminum Housed Resistor

- Die-Casting Aluminum Resistor

- Aluminium Resistor (Multiple Unit)

- Thick Film Resistor

- Braking Resistor Box

- Wirewound Tubular Fixed Resistor

- Power Resistor Unit

- Crowbar Resistor

- Braking Unit

Reactor Vertical Winding Process

Reactor Vertical Winding Process

This product has been discontinued and removed from our shelves.

Product Profile

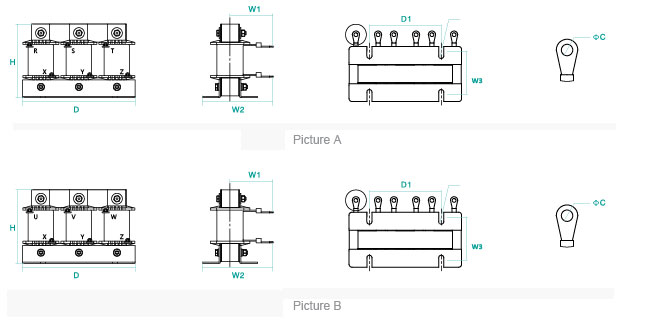

The reactor vertical winding process is mainly used in the single-phase and three-phase reactor with the traditional rated working current ranging from 5-120A. During the application, one or several insulating copper or aluminum flat wire winds the framework of the reactor in the horizontal direction and the winding is often of multiple layers.

Range of Application

Inverter input and output reactor; inverter DC reactor, electric automobile, BOOSTING reactor; other below 120A single-phase and three-phase reactor.

Features

Any product winded by the reactor vertical winding process possesses tidy and beautiful appearance as well as simple and reliable structure. Besides, the winded product is also free of surplus insulation tape (paper) package. The winding, which is directly in contact with air, possesses the advantages of good heat dissipation and low temperature rise.

| Reactor Type | The conventional process test results | The vertical winding process test results | ||

| Coil temperature rise (K) | Core temperature rise (K) | Coil temperature rise (K) | Core temperature rise (K) | |

| ACL-30 | 33.6 | 31.2 | 41.6 | 26.8 |

| ACL-40 | 52.7 | 26 | 62.6 | 28.9 |

| ACL-50 | 36.5 | 23 | ||

| ACL-60 | 50.7 | 13.4 | 41 | 24.3 |

| ACL-80 | 50.1 | 26 | ||

| ACL-90 | 94.8 | 33.9 | 59.1 | 22.4 |

| ACL-120 | 72 | 43.4 | 88.6 | 39.4 |

Comparison Test Report of the OCL series of product (Test method: reactor takes the load for the inverter)

| Reactor Type | The conventional process test results | The vertical winding process test results | ||

| Coil temperature rise (K) | Core temperature rise (K) | Coil temperature rise (K) | Core temperature rise (K) | |

| OCL-30 | 33.6 | 31.2 | 41.6 | 26.8 |

| OCL-40 | 52.7 | 26 | 62.6 | 28.9 |

| OCL-50 | 36.5 | 23 | ||

| OCL-60 | 50.7 | 13.4 | 41 | 24.3 |

ACL Series of Spectrum

ACL Series of Spectrum| Reactor Type | A Current | Length | Width | Height | Installation dimension 1 (mm) | Installation dimension 2 (mm) |

| ACL-0030-EISCL-EM47 | 30 | 200MAX | 116±10 | 130MAX | 72±1 | 120±1 |

| ACL-0040-EISCL-EM35 | 40 | 200MAX | 116±10 | 130MAX | 72±1 | 120±1 |

| ACL-0050-EISCL-EM28 | 50 | 200MAX | 131±10 | 160MAX | 72±1 | 120±1 |

| ACL-0060-EISCL-EM24 | 60 | 200MAX | 131±10 | 160MAX | 72±1 | 120±1 |

| ACL-0080-EISCL-EM17 | 80 | 200MAX | 136±10 | 160MAX | 72±1 | 120±1 |

| ACL-0090-EISCL-EM16 | 90 | 200MAX | 136±10 | 160MAX | 72±1 | 120±1 |

| ACL-0120-EISCL-EM12 | 120 | 200MAX | 171±13 | 160MAX | 92±1 | 120±1 |

| Reactor Type | A Current | Length | Width | Height | Installation dimension 1 (mm) | Installation dimension 2 (mm) |

| OCL-0030-EISCL-EM23 | 30 | 200MAX | 116±10 | 130MAX | 72±1 | 120±1 |

| OCL-0040-EISCL-EM18 | 40 | 200MAX | 116±10 | 130MAX | 72±1 | 120±1 |

| OCL-0050-EISCL-EM14 | 50 | 200MAX | 131±10 | 130MAX | 72±1 | 120±1 |

| OCL-0060-EISCL-EM12 | 60 | 200MAX | 131±10 | 130MAX | 72±1 | 120±1 |