- Laminated Busbar

- Film Capacitor

- Film Capacitor for HEV / EV Motor Control Unit

- DC-Link Capacitor ( Dry-Type, Plastic Case, Maximum Temperature 85℃)

- DC-Link Capacitor ( Dry-Type, Plastic Case, Maximum Temperature 105℃)

- MKP DC-Link Film Capacitor

- Water Cooled Heat Sink

- Flat Heat Pipe

- Reactor

- Water Cooling Reactor

- Input AC Reactor

- Output AC Reactor

- DC Reactor

- Reactor for Explosion-Proof Inverter

- Sine Wave Filter

- Detuned Reactor

- DV/DT Filters

- Three-Phase Input Filter

- Resistor

- Wirewound Resistor

- Aluminum Enclosure Resistor

- Aluminum Housed Resistor

- Die-Casting Aluminum Resistor

- Aluminium Resistor (Multiple Unit)

- Thick Film Resistor

- Braking Resistor Box

- Wirewound Tubular Fixed Resistor

- Power Resistor Unit

- Crowbar Resistor

- Braking Unit

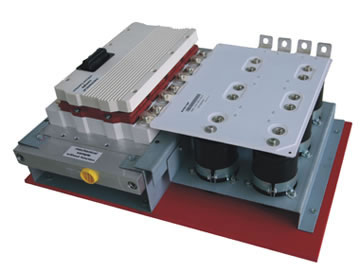

Laminated Busbar

Laminated Busbar

This product has been discontinued and removed from our shelves.

A bus bar consists of one or more flat electrical conductors laminated and electrically insulated by a thin dielectric material which is encapsulated or sealed along the edges. This laminated bus bar could is low lead inductance and saves installation spaces. It is widely applied in Power Electronics, Communication Systems, Transportation and such field to improve system performance and reduce cost.

Features of Laminated Busbar

1. Low stray inductance

2. Minimal impedance, voltage drop

3. Reduce noise, electromagnetism and radio interference

4. Easy to install and maintain

5. Reduce the amount of devices; improve the integration density and reliability of the system

6. Concise and elegant

| Power Electronics: Motor Drives Inverters Wind power UPS systems High density power distribution cabinets Electric welding machines Test Equipment |

Aerospace and Space: Satellite systems Aircraft Missile systems Military: Submarines Communication systems Armored vehicles Radar systems |

| Transportation: Electric locomotives Railway trains Electric vehicles Electric drive ships |

Parameters of Laminated Busbar

1. Cooling method: wind cooling

2. Insulation class: E class for conventional (could be customized)

3. Stray inductance: depends on the structure of product

4. Distributed capacitance: depends on the structure of product

5. Rated voltage: adjustable to customer's requirements

6. Rated current (DC mainly): adjustable with a maximum of 1600A

7. Local discharge: adjustable according to customer's requirement

8. Overload: 100% overload (1 S)

9. Temperature rise: less than 40℃

10. Withstand voltage: AC3500V/50Hz/min

11. Insulated resistance: >10MΩ (DC1000V) Relative air humidity: 90%

12. Working temperature: -30℃~105℃

13. Storage temperature: -40℃~70℃

14. Altitude: Lower than 2000m: rated current

Higher than 2000m: 1% decrease/100 m

Selection of Insulation Materials:

Low lead inductance of Bus bar could be achieved by using excellent insulation materials. In order to meet all the insulation or environmental requirement, customer could choose the below materials for your best application.

| Material | Density (g/cm3) |

Thermal Expansion Coefficient | Thermal Conductivity W/(kg.K) | Permittivity (f=60Hz) | Dielectric Strength (kV/mm) | Flamm- ability Rating |

Continuous Use Temperature (℃) | Water Absorption (%) /24h | Price | General Characteristics |

| NOMEX | 0.8~1.1 | 0.143 | 1.2 | 9 | 94 V-0 | 220 | High | Flame resistance; Thermal resistance; Strong corrosion protection. | ||

| NMN | 1.1~1.3 | 0.136 | 2.4 | 14 | 94 V-1 | 155 | Middle | Good electrical and mechanical performance. High overloading capability. | ||

| DMD | 1.2 | 0.129 | 4.3 | 11 | 94 V-1 | 155 | Low | High temperature proof; excellent electrical and mechanical performance. | ||

| NHN | 1.1 | 0.141 | 4.8 | 8 | 94 V-0 | 155 | High | Good electrical performance; High overloading capability; Flame resistance. | ||

| Polyimide (PI) |

1.42 | 20 | 0.094 | 3.5 | 9 | 94 V-0 | 220 | 0.24 | High | High temperature proof; excellent electrical performance; Radiation resistance; Flame resistance. |

| Polyvinyl Fluoride (PVF) | 1.38 | 53 | 0.126 | 10.4 | 19.7 | 94 V-0 | 105 | 0 | High | Excellent electrical and chemical performance. Low water absorption; Flame resistance. |

| Mylar (PET) | 1.38~1.41 | 60 | 0.128 | 3.8 | 25.6 | 94 V-2 | 120 | 0.1~0.2 | Low | Good electrical performance; Corrosion protection; Low water absorption; Low price. |

| Epoxy Resin | 1.32 | 45~65 | 0.18 | 3.5~4.0 | 15.7 | 94 V-0 | 155 | 0.1 | Low | Stable chemical performance; Low water absorption; Flame resistance. |